Introduction

In the world of modern materials, wood-plastic composite (WPC) has emerged as a game-changer, seamlessly blending the best of both wood and plastic. This innovative material combines two basic materials of WPC—wood fibers and thermoplastics—to create a durable product that mimics the aesthetic appeal of natural wood while offering enhanced resistance to moisture, decay, and pests. The wood-plastic composite manufacturing process allows for a variety of applications, making it a popular choice in construction and outdoor living spaces.

What is Wood-Plastic Composite

Wood-plastic composite (WPC) is an engineered material that utilizes the unique properties of its two basic components: wood fibers and plastic polymers. The result is a versatile product that can be molded into various shapes and sizes, perfect for everything from decking to furniture. By harnessing these two elements, WPC offers an eco-friendly alternative to traditional building materials without compromising on performance or style.

Why Sustainability Matters

Sustainability is more than just a buzzword; it’s an essential principle guiding modern manufacturing practices. As we face increasing environmental challenges, using materials like wood-plastic composites becomes crucial in reducing waste and promoting eco-friendly solutions in construction. By choosing WPC products made from recycled plastics and sustainably sourced wood fibers, consumers can contribute to a greener future while enjoying the numerous advantages offered by this innovative material.

The Growing WPC Market

The wood-plastic composites market scope has expanded significantly in recent years as both homeowners and builders recognize the benefits of this hybrid material. With increasing demand for sustainable building solutions, manufacturers are innovating their offerings by incorporating additives for improved performance in WPC extrusion processes. As more notable projects feature WPC applications—from residential decks to commercial structures—the market shows no signs of slowing down.

Understanding Wood-Plastic Composites

Wood-plastic composites (WPC) are an innovative material that combines the best of both worlds: the natural aesthetics of wood and the durability of plastics. This unique blend offers a versatile solution for various applications, particularly in construction and outdoor living spaces. By understanding the components and processes involved in WPC, we can better appreciate its role in sustainable building solutions.

The Two Basic Materials of WPC

The two basic materials of WPC are wood fibers and thermoplastic resins, which create a composite that is both aesthetically pleasing and functional. Wood fibers can come from recycled wood products or sawdust, making them an environmentally friendly choice. On the other hand, thermoplastic resins provide strength and flexibility to the wood-plastic composite, ensuring it withstands various weather conditions without warping or cracking.

In addition to these primary components, additives for improved performance in WPC extrusion are often included to enhance specific properties such as UV resistance and moisture protection. The combination of these materials results in a product that not only mimics the look of traditional wood but also offers superior durability compared to conventional lumber. This synergy is what makes wood-plastic composites so appealing in today's market.

The Manufacturing Process of WPC

The Wood Plastic Composite (WPC) manufacturing process involves several steps that transform raw materials into high-quality finished products. Initially, wood fibers are blended with thermoplastic resins along with any necessary additives for improved performance during extrusion. This mixture is then heated until it reaches a molten state before being forced through a die to create various shapes such as boards or planks.

Once extruded, the WPC products undergo cooling before being cut into desired lengths, packaged, and prepared for distribution within the expanding wood-plastic composites market scope. Quality control measures ensure that each batch meets industry standards for durability and appearance while minimizing waste throughout production. Understanding this manufacturing process highlights how innovation drives sustainability within the building sector.

Coupling Agent for WPC Explained

A coupling agent plays a crucial role in enhancing the bond between wood fibers and plastic resins within wood-plastic composites (WPC). These agents act as intermediaries that improve adhesion between dissimilar materials, ensuring optimal performance characteristics throughout the life cycle of WPC products. By incorporating coupling agents during production, manufacturers can significantly increase tensile strength while reducing water absorption rates—key factors contributing to overall durability.

Using coupling agents allows for more efficient utilization of resources by maximizing performance without compromising on environmental considerations associated with traditional materials like solid timber or untreated plastics. As consumers become increasingly aware of both advantages and disadvantages of WPC boards in their projects, understanding these enhancements will help them make informed decisions about sustainable building solutions moving forward.

Advantages and Disadvantages of WPC Boards

Wood-plastic composites (WPC) have become a popular choice in various construction and design applications, thanks to their unique blend of materials that offers both aesthetic appeal and functional benefits. However, like any product, they come with their own set of advantages and disadvantages that potential users should carefully consider. Understanding these factors can help in making informed decisions about whether WPC is the right fit for your projects.

Benefits of Using Wood-Plastic Composite

One of the standout advantages of wood-plastic composite is its remarkable durability. The combination of two basic materials—wood fibers and plastic—creates a product that resists rot, decay, and insect damage much better than traditional wood options. Additionally, WPC requires minimal maintenance; unlike wood, there's no need for regular staining or sealing, making the maintenance of WPC floor simpler and more cost-effective over time.

Another significant benefit is the eco-friendliness associated with wood-plastic composites. Many manufacturers utilize recycled plastics in their production processes, contributing to waste reduction while promoting sustainability in the construction industry. This aligns perfectly with the growing Wood-Plastic Composites Market Scope focused on sustainable building solutions that minimize environmental impact.

Moreover, WPC boards are available in a variety of colors and textures which can mimic natural wood without sacrificing performance. With additives for improved performance in WPC extrusion processes, these materials can be engineered to meet specific design needs while maintaining structural integrity under various weather conditions.

Potential Downsides to Consider

While there are many benefits to using wood-plastic composites, it’s essential to consider some potential downsides as well. One notable drawback is that not all WPC products are created equal; variations in quality may arise based on the manufacturing process or the types of additives used during production. This inconsistency can lead to issues such as warping or fading over time if lower-quality materials are chosen.

Another concern is that while WPC does resist many common issues faced by traditional woods—like moisture damage—it isn't completely impervious to them either. Prolonged exposure to harsh conditions can still affect its appearance or structural integrity if proper care isn't taken during installation or maintenance routines.

Lastly, cost can also be a factor when considering wood-plastic composite boards compared to traditional materials like hardwood or treated lumber. While initial costs may be higher due to advanced manufacturing techniques—including coupling agent for WPC usage—the long-term savings from reduced maintenance may offset this investment significantly.

Comparing WPC to Traditional Materials

When comparing wood-plastic composite boards with traditional materials such as solid hardwood or PVC alternatives, several key differences emerge that could influence your decision-making process. For starters, while solid wood offers unmatched beauty and authenticity, it often requires extensive upkeep including regular sealing and staining—something you won't have to worry about with WPC products.

Moreover, durability plays a crucial role; traditional woods are susceptible to rot and insect infestation which makes them less ideal for outdoor applications compared to their composite counterparts made from two basic materials: plastic and recycled wood fibers. In terms of environmental impact as well as lifespan under varying weather conditions, the advantages offered by wood-plastic composites become even more pronounced when evaluated against conventional options.

Ultimately though it boils down to individual preferences regarding aesthetics versus functionality; understanding both sides—the advantages and disadvantages of WPC boards—will help guide you toward making an informed choice tailored specifically for your project needs.

Performance Enhancements in WPC

Wood-Plastic Composites (WPC) have come a long way in terms of performance enhancements, making them an increasingly popular choice for various applications. By integrating specific additives and optimizing the manufacturing process, manufacturers can significantly improve the characteristics of WPC products. As the Wood-Plastic Composites Market Scope expands, understanding these enhancements is vital for both consumers and industry professionals.

Additives for Improved Performance in WPC Extrusion

The use of additives for improved performance in WPC extrusion is essential to achieving desired properties like strength, flexibility, and resistance to environmental factors. These additives can include UV stabilizers that protect against sun damage, colorants for aesthetic appeal, and fire retardants to enhance safety. By carefully selecting the right combination of additives during the Wood Plastic Composite (WPC) manufacturing process, producers can tailor their products to meet specific needs without sacrificing quality.

Moreover, coupling agents play a crucial role in improving the bond between the two basic materials of WPC—wood fibers and plastic resins. This enhanced bonding leads to a more homogeneous material with better mechanical properties and durability. The result is a wood-plastic composite that not only performs better but also lasts longer under various conditions.

Understanding Durability in WPC Products

Durability is one of the primary advantages of using wood-plastic composite materials over traditional options such as solid wood or pure plastic. Thanks to their unique composition, WPC products are resistant to moisture, rot, and insects—common culprits that plague traditional wood materials. This durability means less frequent replacements or repairs are needed over time, making it an attractive option for both residential and commercial applications.

However, it's essential to note that not all wood-plastic composites are created equal; some may incorporate lower-quality materials or inadequate coupling agents that compromise their longevity. Therefore, when evaluating potential purchases within the Wood-Plastic Composites Market Scope, consumers should prioritize quality assurance from reputable manufacturers known for producing durable WPC boards. With proper care and maintenance practices in place—such as regular cleaning—the lifespan of these composites can be extended even further.

WPC Floor Maintenance Tips

Unlike traditional hardwood floors that require extensive upkeep like sanding or refinishing every few years, maintaining a wood-plastic composite floor involves straightforward cleaning methods that save time and effort. Regular sweeping or vacuuming followed by occasional mopping with mild soap solutions will keep your floors looking fresh without damaging them.

It's also worth mentioning that avoiding harsh chemicals is crucial since they can degrade both the plastic components and any protective coatings on your flooring over time. Additionally, placing mats at entry points helps minimize dirt accumulation while protecting your beautiful new floor from scratches caused by grit tracked indoors! By following these maintenance tips consistently—and understanding both the advantages and disadvantages of WPC boards—you'll ensure your investment remains visually appealing while maximizing its durability.

Applications of Wood-Plastic Composites

Wood-Plastic Composites (WPC) are making waves across various sectors, primarily due to their versatility and eco-friendliness. From construction to outdoor living spaces, the applications of WPC showcase its adaptability and sustainability. As the Wood-Plastic Composites Market Scope continues to expand, understanding its specific uses can help highlight the advantages and disadvantages of WPC boards.

Popular Uses in Construction

In construction, wood-plastic composites have become a go-to material for many builders looking to balance aesthetics with durability. The two basic materials of WPC—wood fibers and plastic—combine to create products that resist moisture, decay, and pests. This makes WPC an ideal choice for decking, siding, and even structural components in both residential and commercial buildings.

Moreover, the wood-plastic composite manufacturing process allows for customization in color and texture, providing endless design possibilities. With the growing demand for sustainable building materials, using WPC aligns perfectly with green building initiatives. However, it’s essential to weigh the advantages and disadvantages of WPC boards when considering them for construction projects.

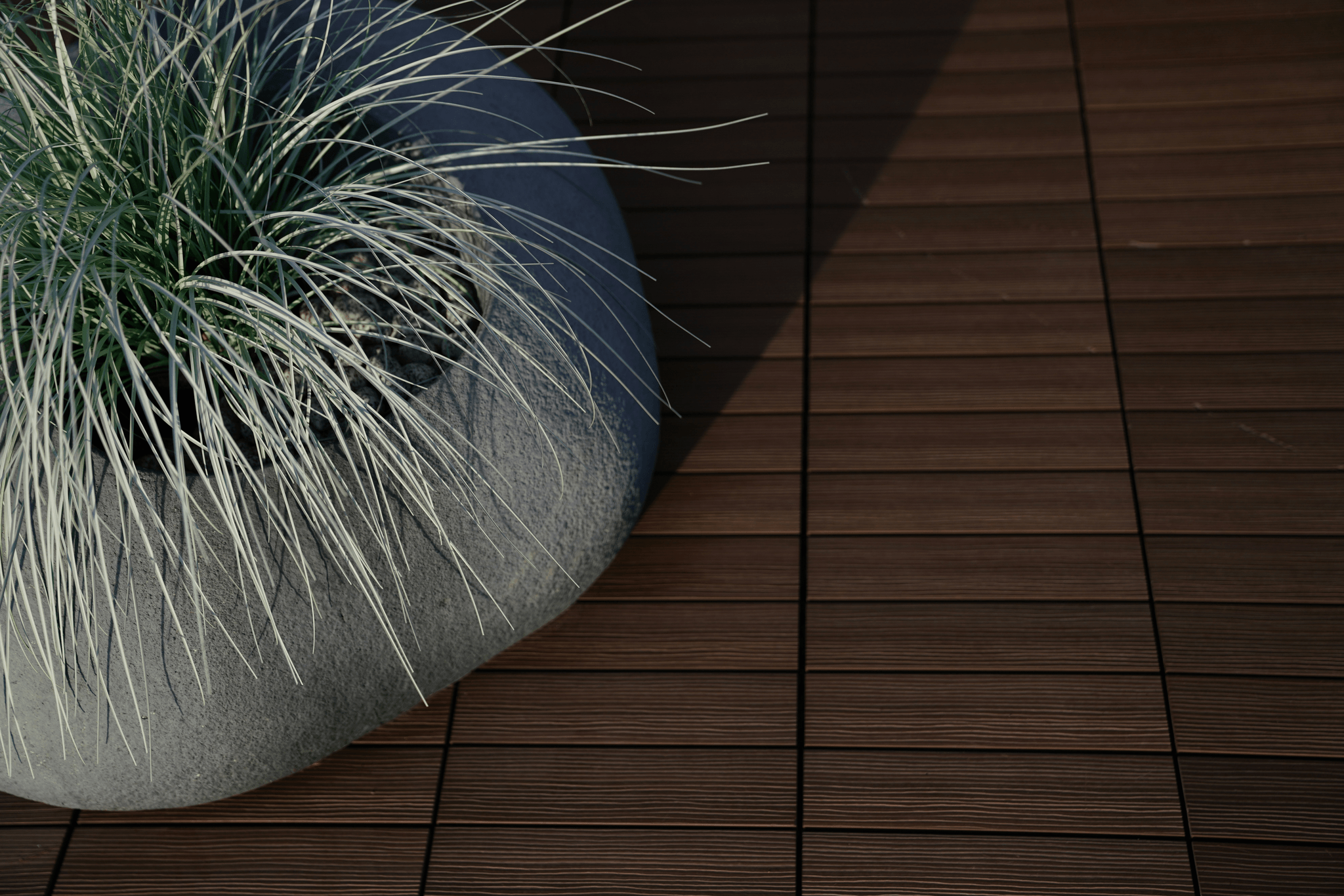

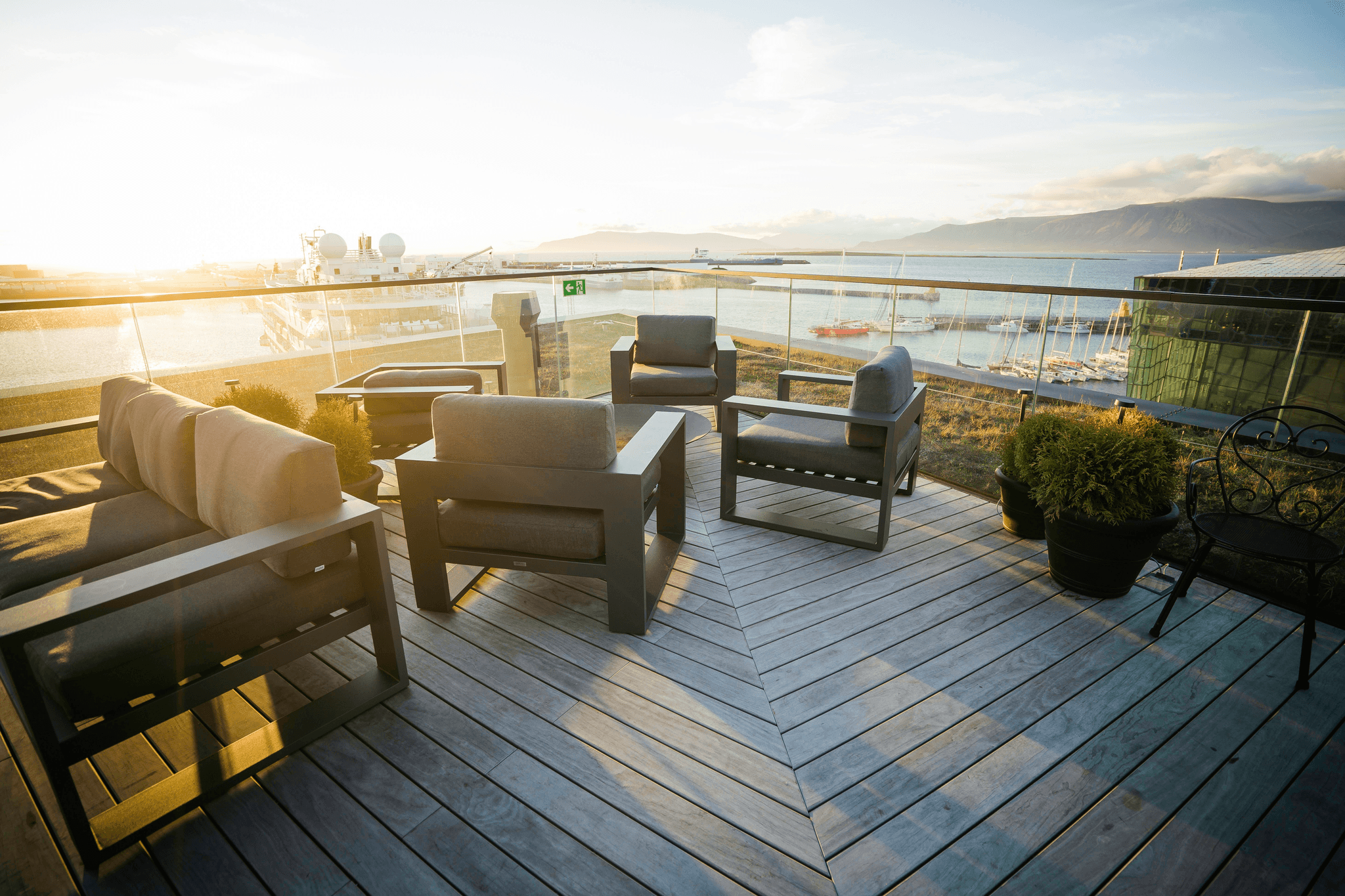

WPC in Outdoor Living Spaces

When it comes to outdoor living spaces, wood-plastic composites shine brightly as a premium choice for decks and patios. Homeowners love how these materials blend seamlessly with nature while offering low maintenance compared to traditional wood options. The maintenance of WPC floor surfaces is minimal; just a periodic cleaning will keep them looking fresh without needing staining or sealing like conventional wood.

Furthermore, because additives for improved performance in WPC extrusion can enhance surface resistance against UV rays and weathering effects, they remain attractive year-round without warping or fading. This makes outdoor spaces not only functional but also visually appealing throughout all seasons. As more people invest in their backyards as extensions of their homes, the demand for high-quality WPC products continues to rise.

Notable Projects Featuring WPC

Several notable projects have successfully integrated wood-plastic composites into their designs, showcasing their versatility on grand scales. From urban parks featuring composite benches made from recycled materials to innovative architectural facades that utilize the coupling agent for WPC effectively—these projects highlight what’s possible with this material blend.

One prime example is a sustainable community development that used WPC extensively in landscaping features such as walkways and seating areas that harmonize with nature while offering durability against wear over time. These innovative applications not only demonstrate the aesthetic appeal of wood-plastic composites but also emphasize their role in promoting sustainability within modern architecture. As we look towards future developments in design innovation within this market scope, it's clear that more groundbreaking projects utilizing these materials will emerge.

The Future of the Wood-Plastic Composites Market

The future of the wood-plastic composites market is looking bright, driven by a combination of sustainability initiatives and innovative design practices. As consumers and industries alike lean towards eco-friendly materials, wood-plastic composite (WPC) products are gaining traction due to their versatility and durability. This shift not only reflects changing consumer preferences but also opens up new opportunities for manufacturers willing to adapt.

Trends Shaping the WPC Market Scope

Several trends are currently shaping the wood-plastic composites market scope, including an increased demand for sustainable building materials and a push for environmentally responsible production methods. The two basic materials of WPC—wood fibers and plastic—are increasingly sourced from recycled or sustainably managed resources, enhancing their appeal in eco-conscious markets. Additionally, innovations in the coupling agent for WPC are improving product performance while minimizing environmental impact.

Another significant trend is the growing popularity of WPC in residential applications, particularly in outdoor spaces like decks and patios. As homeowners seek low-maintenance options that can withstand the elements without sacrificing aesthetics, WPC boards become a go-to solution. Furthermore, advancements in manufacturing processes are allowing for greater customization options, catering to diverse consumer tastes while maintaining cost-effectiveness.

Innovations in Sustainability and Design

Innovations in sustainability and design are at the forefront of advancing wood-plastic composites into mainstream construction materials. Manufacturers are now incorporating additives for improved performance in WPC extrusion that enhance durability without compromising eco-friendliness. These additives not only extend product lifespan but also contribute to better resistance against moisture, UV radiation, and pests—key factors when considering the advantages and disadvantages of WPC boards.

Moreover, designers are increasingly recognizing the aesthetic potential of wood-plastic composites beyond traditional applications; they’re being used creatively in furniture design as well as architectural features. This evolution demonstrates that sustainability does not have to come at the expense of style or functionality—a win-win scenario for both manufacturers and consumers alike! As more innovative designs hit the market, we can expect heightened interest from architects seeking unique solutions that align with sustainable building practices.

Composite Decking Inc's Role in the Industry

Composite Decking Inc is positioning itself as a leader within this burgeoning industry by focusing on quality production methods that prioritize both performance and sustainability. By utilizing advanced wood-plastic composite manufacturing processes alongside state-of-the-art technology, they create products that meet rigorous standards while appealing to environmentally conscious consumers. Their commitment extends beyond just creating durable products; they actively engage with communities about proper maintenance of WPC floor systems to ensure longevity.

Furthermore, Composite Decking Inc is investing heavily in research aimed at developing new formulations that enhance the properties of their wood-plastic composites even further. This proactive approach helps them stay ahead of competitors while contributing valuable insights into industry trends shaping future developments within this sector. With their focus on innovation paired with sustainable practices, Composite Decking Inc sets a benchmark for others aiming to make an impact on both consumers’ lives and our planet’s health.

Conclusion

As we draw our exploration of wood-plastic composites (WPC) to a close, it’s clear that these innovative materials are more than just a passing trend. The combination of the two basic materials of WPC—wood fibers and plastic—creates a product that is not only versatile but also sustainable. With the growing focus on eco-friendly building solutions, choosing wood-plastic composite can be a smart choice for both residential and commercial applications.

Wood-Plastic Composite: A Smart Choice

Wood-plastic composite stands out as an excellent alternative to traditional building materials, offering numerous advantages while minimizing environmental impact. Its unique composition allows for enhanced durability and resistance to elements, making it ideal for outdoor applications like decking and fencing. Moreover, the wood-plastic composite manufacturing process involves repurposing waste materials, contributing positively to sustainability efforts in the construction industry.

Weighing the Pros and Cons

While wood-plastic composites boast many benefits such as low maintenance needs and resistance to rot, it's essential to weigh the advantages and disadvantages of WPC boards before making a decision. On one hand, you have their impressive longevity and aesthetic appeal; on the other hand, some may find them less natural in appearance compared to solid wood options. Understanding these factors will help you make an informed choice that aligns with your project goals.

The Future of Sustainable Building Solutions

Looking ahead, the wood-plastic composites market scope is set for substantial growth as innovations continue to emerge in sustainability and design trends. Additives for improved performance in WPC extrusion are paving the way for even greater advancements in quality and functionality. As companies like Composite Decking Inc lead the charge in transforming how we think about building materials, it’s clear that wood-plastic composite is not just a fleeting option but rather a cornerstone of future sustainable building solutions.