Introduction

Enter Wood Plastic Composite (WPC) decking, a modern solution that combines the best of both worlds—durability and aesthetic appeal. With its unique blend of materials, decking made from recycled plastic is rapidly gaining popularity among homeowners and builders alike.

Understanding Wood Plastic Composite Decking

WPC decking is a composite material that combines recycled plastic with natural wood fibers, resulting in a product that mimics the look and feel of traditional wood without many of its drawbacks. This innovative mix creates deck boards that are not only visually appealing but also resistant to rot, mold, and insects. The result is composite wood decking boards that offer longevity and performance for any outdoor space.

Benefits of Using WPC Decking

One of the standout benefits of using WPC decking is its eco-friendliness; by utilizing recycled plastic materials, this type of composite decking helps reduce waste while providing a sustainable building option. Additionally, deck composite decking requires minimal maintenance compared to traditional wood options—no sanding or staining necessary! Homeowners can enjoy their outdoor spaces without worrying about constant upkeep or deterioration over time.

How WPC is Different from Traditional Decking

Unlike traditional wooden decks that require regular treatments to maintain their appearance and structural integrity, composite wood offers a hassle-free experience with superior resistance to weather elements. This makes composite decking installation straightforward and less labor-intensive than its wooden counterparts. Ultimately, choosing WPC means investing in a long-lasting solution that looks great year after year while being kinder to our planet.

The Components of WPC Decking

Wood Plastic Composite (WPC) decking is a marvel of modern engineering, combining the best features of wood and plastic to create a durable and attractive outdoor surface. Understanding the components that make up this innovative material can help homeowners appreciate its advantages over traditional options. Let’s dive into the essential ingredients that give WPC decking its unique properties.

Recycled Plastic Materials

At the heart of decking made from recycled plastic is, well, recycled plastic! This eco-friendly material typically comes from post-consumer waste such as bottles and containers, diverting them from landfills and reducing environmental impact. By incorporating these recycled plastics into composite decking, manufacturers not only enhance sustainability but also improve resistance to moisture and mold—two common enemies of traditional wood decks.

The use of recycled plastic in deck composite decking means you’re choosing a product that contributes positively to the environment while enjoying a low-maintenance solution for your outdoor space. This clever recycling process also ensures that your deck boards are less likely to warp or crack compared to their wooden counterparts. So every time you step onto your composite wood decking boards, you can feel good knowing you're walking on an environmentally friendly surface!

Natural Wood Fibers

While it might seem counterintuitive for a product made primarily from plastic, natural wood fibers play an essential role in WPC decking as well. These fibers are typically sourced from reclaimed wood scraps or sawdust, providing an authentic look and feel reminiscent of traditional timber without sacrificing durability. The combination of recycled plastic materials with natural wood fibers results in composite wood that boasts both aesthetic appeal and structural integrity.

Incorporating these natural elements into composite decking installation allows for a beautiful finish that mimics real wood grain patterns while offering enhanced performance characteristics like resistance to splintering or fading over time. Plus, using wood fibers helps maintain the warmth associated with wooden decks while ensuring longevity—making it easier for homeowners to enjoy their outdoor spaces without constant upkeep! With this blend of materials, your deck boards are not just functional; they’re stylish too!

Additives for Durability

To ensure long-lasting performance in all weather conditions, various additives are introduced during the manufacturing process of WPC decking. These additives serve multiple purposes: enhancing color stability, improving UV resistance, and increasing overall durability against wear-and-tear from foot traffic or furniture placement on your deck composite decking surface. With these enhancements integrated into the design, homeowners can expect their composite wood decking boards to withstand the test of time.

Moreover, some formulations include anti-fungal agents that prevent mold growth—a common concern for those living in humid climates where traditional wooden decks often fall short due to moisture absorption issues. By incorporating these smart additives into WPC products, manufacturers have created a solution that's not only visually appealing but also robust enough for years of enjoyment with minimal maintenance required! So whether you're hosting summer barbecues or simply relaxing outdoors with a book in hand on your new deck boards, rest assured they’ll hold up beautifully against nature's challenges.

The Manufacturing Process of WPC Decking

The manufacturing process of WPC (Wood Plastic Composite) decking is a fascinating blend of technology and sustainability. It starts with sourcing the right materials, primarily recycled plastic and natural wood fibers, which are combined to create a product that is both durable and eco-friendly. Understanding this process can help consumers appreciate the quality and effort that goes into creating composite decking options available in today’s market.

Mixing and Extrusion

The first step in crafting composite wood decking boards involves mixing recycled plastic materials with natural wood fibers. This combination is essential for achieving the desired balance of strength and aesthetics in the finished product. Once mixed, the material undergoes an extrusion process where it is heated and forced through a mold to form long deck boards, ready for further shaping.

Extrusion not only shapes the material but also ensures that it retains its unique properties, such as resistance to moisture and pests—key advantages when compared to traditional decking options. The result is a continuous length of composite decking that can be cut into various sizes depending on project requirements. This efficient method allows manufacturers to produce large quantities of deck composite decking while maintaining consistent quality.

Molding Techniques

After extrusion, various molding techniques come into play to enhance the visual appeal and functionality of WPC decking products. These methods allow manufacturers to create textured surfaces that mimic natural wood grain, giving consumers a variety of aesthetic choices without sacrificing durability. Common techniques include compression molding or injection molding, each contributing uniquely to how deck boards are finished.

These molds not only shape the boards but also ensure they are uniform in thickness and density—important factors for proper installation later on. Additionally, using molds can reduce waste by maximizing material usage during production, making it an eco-friendly choice aligned with the principles behind composite wood products made from recycled resources. Ultimately, these advanced molding techniques lead to high-quality composite wood decking boards that stand out in both performance and appearance.

Quality Control Measures

Quality control measures are integral throughout the manufacturing process of composite decking installation products; they ensure that every batch meets stringent standards before reaching consumers’ hands. Manufacturers conduct regular testing on physical properties such as tensile strength, moisture absorption rates, and UV resistance—ensuring longevity even under harsh weather conditions common for outdoor applications.

Moreover, inspections occur at multiple stages—from raw materials entering production lines to finished deck boards ready for shipment—guaranteeing consistency across all units produced. By prioritizing quality control in their processes, companies reinforce consumer trust in their offerings while promoting sustainable practices within the industry focused on producing high-quality decks made from recycled plastic materials.

Benefits of Decking Made from Recycled Plastic

When it comes to choosing the right decking for your outdoor space, decking made from recycled plastic offers a treasure trove of benefits. Not only does it provide an eco-friendly alternative to traditional materials, but it also boasts impressive longevity and maintenance advantages. Plus, the aesthetic appeal of composite wood decking boards can elevate any backyard into a stylish retreat.

Eco-Friendly Advantages

One of the most significant eco-friendly advantages of composite decking is its role in reducing waste. By utilizing recycled plastic materials, this innovative product helps divert plastic from landfills while conserving natural resources. Choosing deck composite decking means you're not just enhancing your outdoor space; you're also making a positive impact on the environment.

Additionally, many manufacturers prioritize sustainability in their production processes, ensuring that their composite wood decking boards are sourced responsibly. This commitment to eco-friendliness extends beyond just the materials used; it often includes energy-efficient manufacturing practices as well. So when you opt for decking made from recycled plastic, you’re supporting a greener future!

Longevity and Maintenance

Longevity is another compelling reason to consider composite wood when selecting your next deck boards. Unlike traditional wood options that may warp or rot over time, composite decking is designed to withstand the elements without succumbing to wear and tear easily. This durability translates into less hassle and fewer expenses on repairs or replacements down the line.

Maintenance is also a breeze with this type of deck composite decking; there’s no need for regular staining or sealing like you would with conventional lumber. A simple wash with soap and water will keep your deck looking pristine for years to come! With such low maintenance requirements, you can spend more time enjoying your outdoor oasis rather than worrying about upkeep.

Aesthetic Appeal

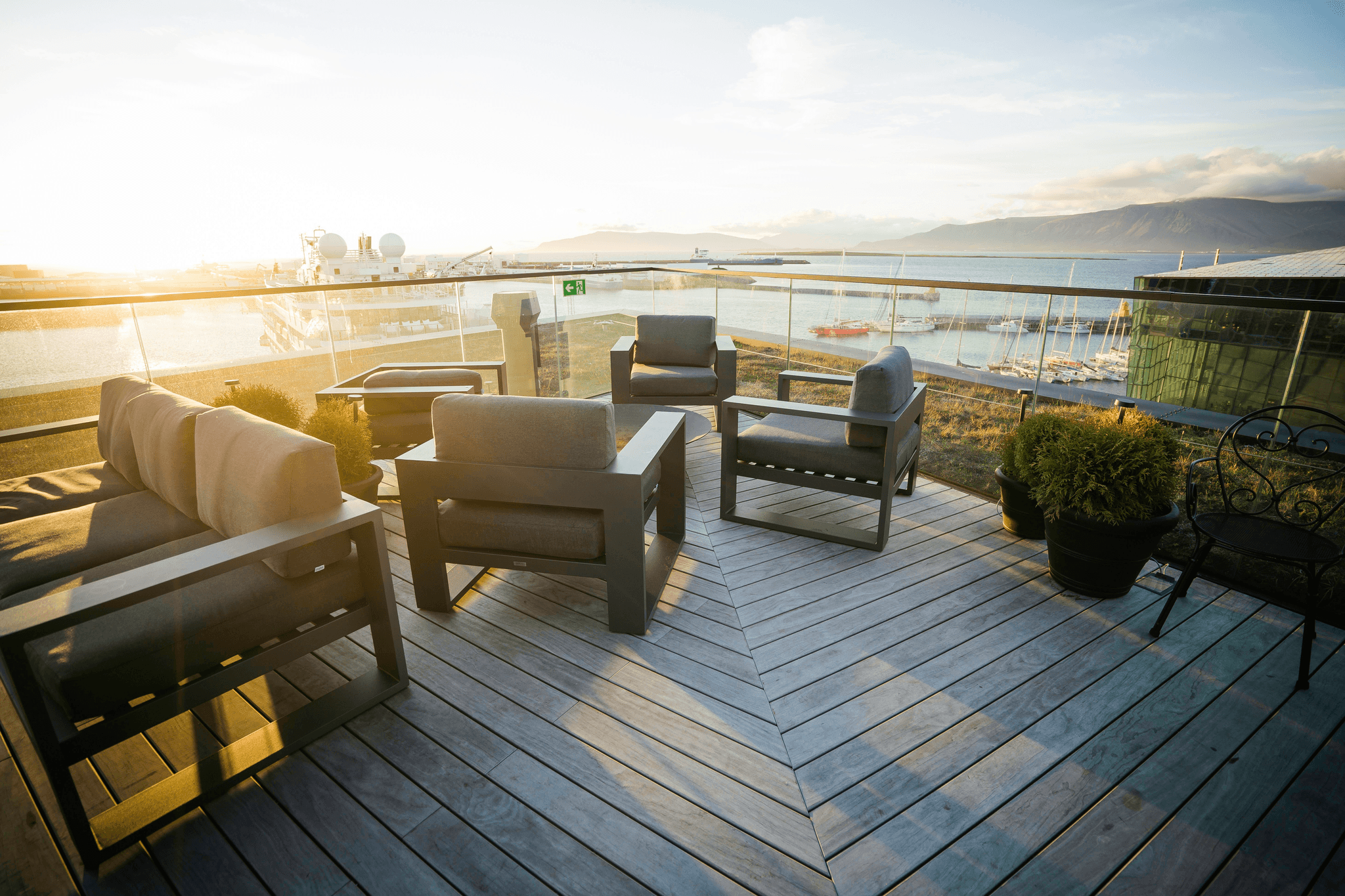

Finally, let’s talk about aesthetics—the cherry on top of why so many homeowners are turning to composite wood for their decks! The variety of colors and textures available in composite wood decking boards allows you to customize your outdoor space effortlessly while achieving a polished look that rivals traditional materials. Whether you prefer a classic wooden appearance or something more modern, there's likely a style that suits your taste perfectly.

Furthermore, advancements in technology have led to realistic finishes that mimic natural wood grain patterns beautifully without sacrificing performance or sustainability. As such, choosing decking made from recycled plastic doesn’t mean compromising on style—it enhances it! With all these factors combined, it's clear why so many people are making the switch to composite options for their outdoor living areas.

Installation of Composite Decking

Installing composite decking can be a rewarding DIY project that enhances the beauty of your outdoor space while providing durability and low maintenance. Before diving into the installation, it’s essential to prepare adequately to ensure a smooth process. This section will guide you through pre-installation preparation, a step-by-step installation guide, and tips for achieving a flawless finish with your deck boards.

Pre-Installation Preparation

Before you start laying down those beautiful composite wood decking boards, it's crucial to gather all necessary tools and materials. You’ll need a saw, drill, measuring tape, level, and of course, your chosen composite decking materials made from recycled plastic. Additionally, check local building codes to ensure compliance; this could save you headaches down the road!

Next up is measuring your deck area accurately—this will help you determine how many deck boards you'll need. Make sure the area is clear of debris and any old materials that could interfere with your new installation. Lastly, allow your composite wood to acclimate for at least 48 hours in its intended environment; this helps prevent expansion or contraction once installed.

Step-by-Step Installation Guide

Now that you’re prepped and ready to go, let’s dive into the actual composite decking installation process! Start by laying out the joists according to your design plan; typically spaced 16 inches apart works well for most applications. Use treated lumber or metal brackets for greater longevity since these will support your deck composite decking.

Once the joists are in place, begin installing the first row of deck boards using hidden fasteners or screws designed specifically for composite wood. Ensure each board is level before moving on; this will keep everything looking sharp! Continue laying each subsequent row until you've covered the entire area—don’t forget to leave gaps between boards as recommended by manufacturers for proper drainage.

Tips for a Perfect Finish

To achieve that picture-perfect look with your new composite decking made from recycled plastic, attention to detail is key! Start with checking alignment frequently as you install each board; nothing says DIY like a wonky-looking deck! You can also use spacers between boards during installation to maintain consistent gaps.

Once all deck boards are laid down, consider applying a suitable sealant if recommended by the manufacturer—this can enhance durability and protect against stains or scratches over time! Finally, take some time for cleanup: sweep away any debris and give everything one last inspection before inviting friends over for that inaugural barbecue on your stunning new outdoor space.

Popular Brands and Products in WPC Decking

When it comes to decking made from recycled plastic, several brands stand out in the composite decking market. These companies offer a range of products designed to meet diverse aesthetic preferences and functional needs. From budget-friendly options to high-end selections, there’s something for everyone looking to enhance their outdoor spaces with composite wood decking boards.

Composite Decking Inc Overview

Composite Decking Inc is a prominent player in the world of composite decking, known for its innovative approach to creating deck boards that blend durability with style. Their products are primarily made from recycled plastic and natural wood fibers, ensuring both eco-friendliness and longevity. With a commitment to quality, the company offers an extensive range of colors and textures that mimic traditional wood while providing superior resistance to moisture and fading.

The beauty of Composite Decking Inc lies not only in its product offerings but also in its dedication to sustainable practices. By utilizing materials that would otherwise end up in landfills, they contribute significantly to reducing environmental impact. Customers frequently rave about how easy their composite decking installation is, making it a popular choice among DIY enthusiasts.

Other Leading Manufacturers

Apart from Composite Decking Inc, several other manufacturers have carved out their niche in the composite decking landscape. Brands like TimberTech and Trex have established themselves as leaders by consistently delivering high-quality deck composite decking solutions that cater to various consumer needs. These companies also focus on producing environmentally friendly products that combine aesthetics with performance.

TimberTech’s offerings include a wide selection of colors and finishes designed for both contemporary and classic tastes, while Trex is renowned for its low-maintenance options that resist fading and staining. Both brands emphasize innovation and sustainability in their manufacturing processes, ensuring that customers receive durable products built from recycled materials without compromising on style or functionality.

Comparing Product Lines

When comparing product lines across different brands of composite wood decking boards, it becomes clear that each manufacturer has unique selling points worth considering. For instance, while some brands may excel in color variety or texture realism, others might focus on affordability or ease of installation—crucial factors for many homeowners embarking on a new project.

It’s essential for consumers to assess their specific needs when choosing between these options; whether prioritizing aesthetics or long-term durability can greatly influence satisfaction levels post-installation. Additionally, understanding warranty terms can help buyers make informed decisions regarding which deck boards will best suit their lifestyle requirements over time.

In conclusion, exploring popular brands reveals an exciting array of choices available within the realm of WPC decking—each brand offering distinct advantages tailored for various preferences and budgets.

Conclusion

In summary, the choice of decking materials can significantly impact both the environment and your outdoor living experience. Wood Plastic Composite (WPC) decking stands out as a superior alternative to traditional options, offering durability, aesthetic appeal, and eco-friendly benefits. With its unique blend of recycled plastic materials and natural wood fibers, decking made from recycled plastic is not only practical but also stylish.

Why Choose WPC Over Traditional Options

Choosing WPC over traditional wood or other materials can save you time and money in the long run. Unlike conventional wood decks that require regular staining and sealing, composite wood decking boards are designed to withstand the elements with minimal maintenance. Plus, with their resistance to fading, splintering, and rotting, these deck boards ensure that your outdoor space remains inviting for years to come.

Moreover, composite decking installation is straightforward compared to traditional methods that often involve complex cutting and fitting processes. You’ll find that many brands offer user-friendly systems for easy setup—perfect for DIY enthusiasts! It’s clear that opting for deck composite decking means less hassle and more enjoyment.

The Future of Eco-Friendly Decking

As environmental awareness grows among consumers, the demand for sustainable building materials like composite wood continues to rise. The future of eco-friendly decking looks bright as manufacturers innovate new ways to incorporate even more recycled content into their products. This not only reduces waste but also promotes a circular economy where materials are reused rather than discarded.

Additionally, advancements in technology mean that future iterations of composite wood will likely offer enhanced durability and aesthetics while remaining environmentally friendly. Expect exciting developments in colors and textures that mimic natural wood without sacrificing performance! As we move forward into a greener future, WPC will likely play a pivotal role in transforming how we think about outdoor spaces.

Exploring More Composite Decking Options

With an increasing variety of options on the market today, exploring different types of composite decking has never been easier or more exciting! From various colors to textures resembling exotic hardwoods or classic pine finishes, there’s something for every taste when it comes to deck boards made from recycled plastic materials. Brands are continually expanding their product lines to cater to diverse preferences while maintaining quality standards.

If you're considering upgrading your outdoor area with composite wood or looking into new trends in design or sustainability features—there's no shortage of choices available now! So why not dive deeper into what’s out there? With countless possibilities awaiting you in the world of composite decking installation, transforming your backyard into an oasis has never been so achievable!